- FläktGroup

- FläktGroup Insights: Driving Innovation

- Optimising AHU Design for Active Chilled Beam Systems

Optimising AHU Design for Active Chilled Beam Systems

- Theme

- Sustainable performance

- Reading time

- 10:00

- Published

- By

- David Black

Active chilled beam systems offer significant energy efficiency advantages over your traditional fan coil units. However, they require precise control of humidity and temperature to prevent condensation and maintain optimal indoor comfort. Let’s explore the optimal Air Handling Unit (AHU) configurations for chilled beam applications, focussing on dehumidification strategies and the benefits of twin rotor systems.

Why Chilled Beam Systems Demand Special Attention

Unlike fan coil systems, active chilled beams rely on dry water coils at room level to avoid condensation. If not controlled the result can be “indoor rain.”

This means the primary air must be dehumidified before entering the room. An AHU plays a critical role in maintaining indoor dew point and relative humidity to ensure both occupant comfort and system performance.

Humidity Control and Dew Point Management

The required ventilation rate is determined by national regulations, client specifications and application type. To maintain humidity within design parameters, the primary ait must be supplied at a flow rate and dew point that offsets the latent gains in the occupant zone.

Typical room setpoints are as follows:

- 24°C dry bulb / 50% RH → Dew point ≈ 12.9°C

- 25°C dry bulb / 50% RH → Dew point ≈ 14°C

To prevent condensation on chilled beam coils, chilled water is supplied 1°C above the dew point, typically at 14°C, with a return temperature of 17°C. This results in a mean water temperature of 15.5°C, optimising thermal performance.

Condensation Prevention with BMS Controls

To avoid condensation risks, the following Building Management System (BMS) strategies are recommended:

- Monitor internal relative humidity to ensure chilled water temperature remains above dew point

- Use condensation sensors to shut off chilled water supply when condensation is detected, this is important in spaces with openable windows.

However, these strategies result in reduced chilled beam cooling capacity when the external conditions are higher than the design temperatures and humidity – an increasing situation because of climate change.

Challenges with External Humidity

External humidity often exceeds design conditions. For example, a typical design condition in London is 32°C / 50% relative humidity (RH) but actual humidity is often higher. On hot days, this results in an increase in the chilled beam water temperature, reducing cooling capacity when it is needed most.

This can be clearly illustrated in the above reported weather graph for London, which shows that relative humidity remains consistently above 50% for most of the year. Here the graph tracks temperature and humidity from January 2024 to January 2025, highlighting the seasonal changes. Even during those peak summer temperatures, humidity levels often exceed design expectations. This reinforces the need for well delivered dehumidification strategies within AHU design.

Energy Efficiency Advantages of Chilled Beam Systems

Despite these challenges that are posed by high external humidity, chilled beams systems offer notable energy efficiency benefits over traditional fan coil units. One key advantage lies in the higher operating temperatures of the chilled beam system. A chiller running at 14/17°C is significantly more efficient than one operating at 6/12°C [1] resulting in:

- Lower energy consumption

- Reduced CO2 emissions

- Improved overall system efficiency

The benefits of the more efficient chiller are ideally matched to FläktGroup’s iQ STAR chilled beam range, which is designed for ventilation, cooling and heating. With its flow pattern control and adjustable induction, it supports in providing comfort and flexibility in those high demanding indoor environments.

This efficiency gain proves particularly valuable in modern buildings aiming to meet sustainability targets and with our full range of chilled beams being EPD certified you’re sure to meet those targets.

Additionally, when paired with one of our AHUs that manage humidity and temperature, our chilled beam systems can outperform even the most advanced VAV fan coil setups.

iQ STAR WEGA® II

A high-performance active chilled beam system designed to deliver ventilation, cooling, and heating with exceptional comfort and flexibility in commercial and institutional buildings.

The iQ STAR WEGA® II is engineered to optimise indoor climate through Flow Pattern Control and adjustable induction, ensuring precise air distribution and occupant comfort in a wide range of room layouts and usage scenarios. This makes it an ideal fit for Demand Controlled (DCV) applications.

This ceiling-flush chilled beam integrates seamlessly into modern HVAC systems, supporting energy-efficient operation and low lifecycle costs. Its modular design and adaptability make it ideal for both new builds and retrofit applications where performance, aesthetics, and sustainability are key.

Features of the iQ STAR WEGA® II include:

- Flow Pattern Control for optimised air distribution

- Adjustable induction for tailored comfort and performance

- Pressure independent Pi function actuator for airflow control

- Integrated ventilation, cooling, and heating in one compact unit

- Ceiling-flush design for discreet architectural integration

- EPD-certified for sustainability and compliance with green building standards.

Why AHU Dehumidification is Critical in Chilled Beam Systems

In active chilled beam systems, humidity control is not optional – it is essential. Since chilled beams operate with dry coils to avoid condensation, all moisture removal must be handled by the central AHU.

To maintain comfort and prevent condensation, the AHU must deliver primary air at a specific moisture content, typically around 8g/Kg (REHVA guidebook shows figure ranges from 7.1 to 9.4) [2]. This ensures that the room dew point stays below the chilled water temperature, protecting the beam coils and maintaining system performance.

Traditional Approach: Effective but Costly

AHU dehumidification traditionally has been achieved by:

- Cooling the air to a dew point around 12°C to remove moisture

- Reheating the air to a comfortable supply temperature eg 18°C before it enters the space

- Using a sorption rotor to pre-condition the air and reduce the load on the cooling coil

This may be an effective method, but it requires:

- A large cooling coil and high-capacity chiller

- A reheat coil and a heat source (traditionally a gas boiler, now often a heat pump)

- Significant installation costs – air source heat pumps have a significantly higher total cost of installation than gas fired boiler

Installing a heat pump reheat system can cost €500 per installed kW, which is a huge expenditure to any project.

The FläktGroup Advantage: Twin Rotor AHU Design

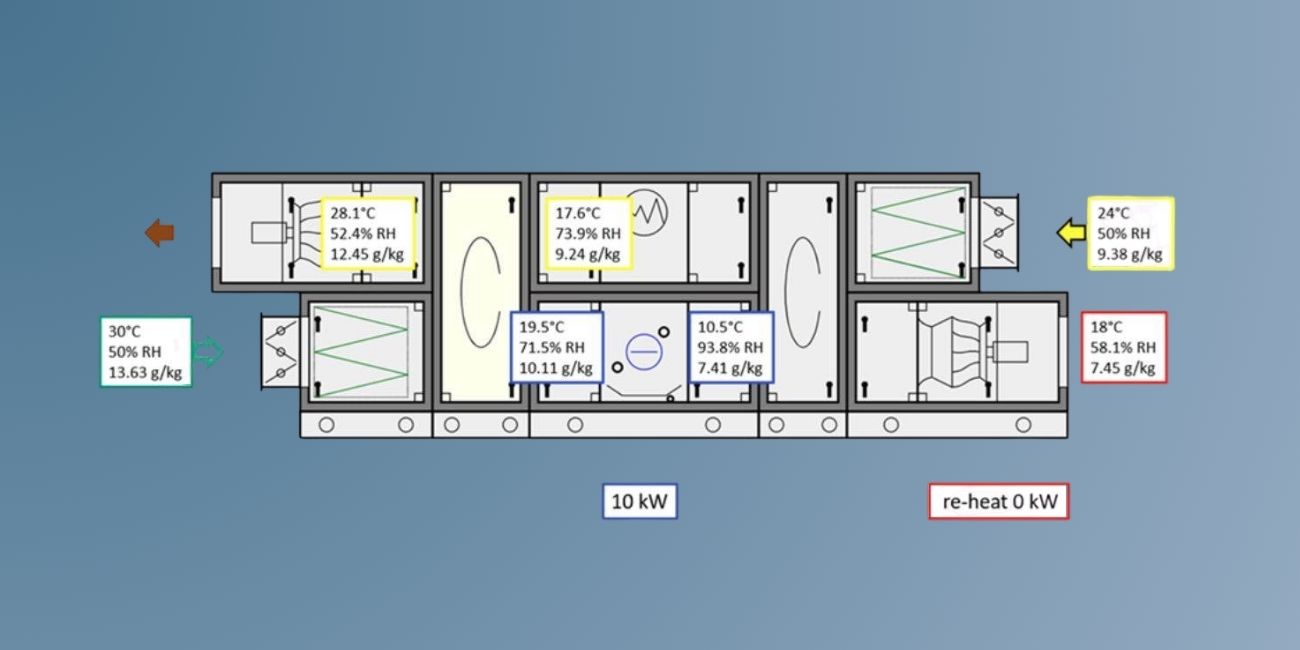

Out twin rotor AHU solution offers a smarter, more efficient alternative – delivering the required supply air condition without the need for reheat.

Here’s a breakdown of how this system works:

- The first rotor (sorption) removes moisture and precools the air

- The cooling coil then brings the air to dew point, thus remove any latent load

- The second rotor uses extract air to reheat the supply air to 18°C – without any additional heating source

Performance and Cost Benefits

This approach provides so many benefits such as:

- Reducing cooling coil load by up to 60%

- Eliminating the need for a heat pump or boiler

- Delivering stable humidity control, ensuring optimal chilled beam performance

- Lowering both financial and operating costs

- Per 1 m³/s airflow:

- 15 kW reduction in cooling coil size

- 9kW reduction in heating coil size

- €12,000 installation cost saving

For designers and installers, this means:

- Simpler system design

- Fewer components to install and commission

- Smaller chiller and no heat pump or boiler required

For end users, it means:

- Lower energy bills

- Reduced carbon emissions

- More reliable indoor climate control

eQ MASTER® Twin Wheel Air Handling Unit

COMING SOON together with ISYteq 4.0. Integrated control system for better optimisation and easier commissioning.

A high-performance modular air handling solution designed to deliver superior indoor air quality, energy efficiency, and adaptability across commercial and industrial environments.

The eQ MASTER® Twin Wheel Unit offers exceptional airflow and supply humidity control. Its intelligent design ensures low energy consumption, quiet operation, and simplified installation—making it a reliable and sustainable choice for modern buildings.

Our eQ MASTER® Twin Wheel integrates seamlessly with advanced energy recovery systems and smart controls, providing a complete solution for efficient climate management. The modular concept supports scalability and customisation, ensuring your system evolves with your requirements.

Features of the eQ MASTER® Twin Wheel unit include:

- Modular design with 21 sizes and airflow up to 12 m³/s

- 1st rotor - FläktGroup High-efficiency sorption to dehumidify fresh air

- 2nd rotor – FläktGroup high efficiency condensation rotor for “free” reheat

- Integrated controls regulate the cooling coil to dehumidify to the required supply enthalpy

- Part of a system solution perfectly matched to FläktGroup chilled beams

Energy demander impact (Per 1 m3/s)

| Twin Wheel | Single Wheel | @ | Single Wheel | |

Engery demand impact (Per 1 m3/s)

| Twin Wheel | Single Wheel | @ | Single Wheel | |

| Heating | 0 kWh | 19,100 kWh | 0.05 €/kWh | +1K € |

| Cooling | 11,802 kWh | 28,980 kWh | 0.03 €/kWh | +0.5K € |

| Supply Fan | 3,705 kWh | 2,838 kWh | 0.20 €/kWh | -0.2K € |

| Exhaust Fan | 5,010 kWh | 2,708 kWh | 0.20 €/kWh | -0.5K € |

| Summary | 20,517 kWh | 53,626 kWh | +0.8 € |

Electricity @ 0.2 €/kWh.

Air source heat pump SCOP of 3.5, so cost per kWh = 0.05 €/kWh.

Chiller SEER of 7.0, so cost per kWh = 0.03 €/kWh.

Running cost analysis

Fan energy use does increase slightly with the inclusion of a second rotor, but the overall running costs are lower thanks to reducing cooling and heating demand. Due to lower energy demand, carbon emissions are also significantly reduced too.

Twin Rotor - A Smarter, More Efficient System Approach

Our twin rotor AHU solution cannot be overstated for its importance in proving optimal savings and building comfort. Buildings are facing increasing pressure to meet environmental standards, so it is vital that any system that is in place meets these demands. With the pairing of our range of EPD certified chilled beams, we provide a valuable alternative to a traditional fan coil system.

This alternative solution aims to deliver superior performance, lower costs and greater sustainability.

Key Benefits of Twin Rotor AHUs in Chilled Beam Installations

- Lower overall installation costs – Reduced need for large chillers, reheat coils and heat sources

- Lower running costs – Efficient humidity control and reduced energy demand

- Stable indoor climate – Precise regulation of supply air moisture ensures optimal chilled beam performance and occupant comfort

Why Chilled Beams Make Sense

Chilled beams like the iQ STAR WEGA II are engineered to operate without surface water, eliminating the need for filters or drainage systems [3]. This reduces:

- Maintenance requirements

- Capital costs

- Operational risks

Chilled beams are an alternative to fan coils and even when compared to the most efficient fan coils, chilled beams offer:

- Lower energy consumption

- Higher chiller efficiency (especially at 14°C chilled water setpoints)

- Reduced peak cooling demand

- Smaller chiller footprint

Centralised Efficiency

Dry cooling systems rely on sufficient air supply to manage latent loads. In high humidity environments, centralised AHUs:

- Handle latent cooling

- Use high-efficiency fans for air distribution

- Avoid inefficiencies of decentralised room units

System-Level Gains

By separating chilled water production for the AHU and chilled beams, designers can optimise each system:

- AHU chilled water handles latent loads

- Beam chilled water operates at higher temperatures, improving chiller performance and reducing energy use

In summary, our twin rotor AHUs and chilled beams combined forms a high performance and low-carbon solution. This system solution delivers measurable value across design, installation and operation. It’s a strategic solution for designers, installers, and building owners seeking better outcomes — technically, financially, and environmentally.

References

2. REHVA Guidebook, Active and Passive Beam Application Design Guide For Global Application. 2015