- FläktGroup

- Solutions

- Hospital Ventilation

Hospital Ventilation

Ventilation Systems in Hospitals create a unique set of challenges for air treatment since they are very complex buildings that contain a variety of room types with specific demands.

Competence where reliance in hygiene and trust is essential

In areas in where, apart from the climate comfort, high hygiene is required such as in the medicine, nursing, pharma and life science applications, building climate control has a crucial role. The ventilation system must ensure that patients, visitors and staff feel comfortable while at the same time the strict hygiene requirements must be equally satisfied. Investors, planners and facility managers ultimately demand the highest possible energy efficiency in order to minimize operating costs.

A high measure of competence and specialised experience is a prerequisite for highly dependable room-air and process-air technology in the healthcare and pharmaceutical industry. All around the globe, consumers demand high-quality medications for prevention, diagnosis, and treatment of diseases. With a long history and thousands of reference installations we have established ourselves as a competent value-adding partner. The recipe for success is especially conceived filter technologies and ventilation systems as well as room elements and components.

A dependable partner

Proven competence and specialised experience is a prerequisite for highly dependable room-air and process-air technology in the life science industry. For this reason, numerous international manufacturers trust FläktGroup‘s system solutions.

All around the globe, consumers demand high-quality medications for prevention, diagnosis, and treatment of disease. The health and life-sciences sector is growing dynamically at an above-average rate. We offer solutions for safe heat and cooling recovery, safe air filtration, reduced air pollution, cleaning and air distribution supporting low life cycle costs and high hygiene requirements.

For decades, FläktGroup has established itself as a competent value-added partner for the life science industries.

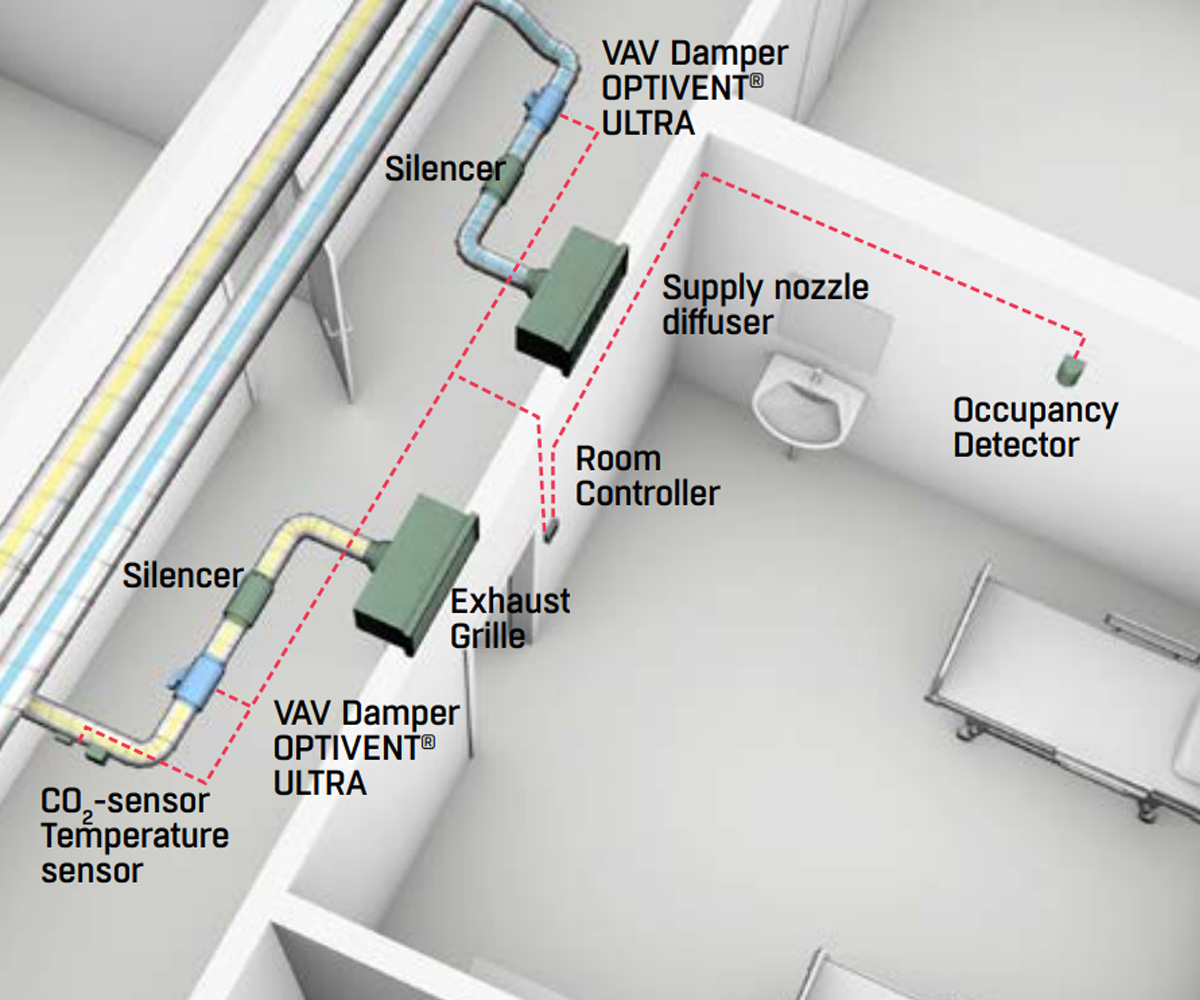

Ventilation of Hospital/Patient room

Supporting comfort and hygiene in demanding spaces

Medical facilities have high requirements. Also in patient wards demands are high. Weak and sick patients should be given good recovery conditions and need no extra strain from bad air quality or comfort.

A special demand is put on the ventilation system to be easy to maintain without affecting the daily operations, when premises are occupied 24/7.

Patient Room

Area 25 m2 Air volume +/- 38 l/s

Proposed Solution

PROPOSED DESIGN FUNCTIONS

- CO2-, temperature and occupancy sensors are observing room’s indoor air climate

- Room controller receives messages from the different room sensors and controls the VAV dampers

- The room ventilation is supplied by Demand Controlled Ventilation

OPTIVENT® ULTRA BENEFITS

- Needs no safety distance in the tight duct installation in the corridor

- Dust resilient construction is needed for the patient room because of fabric dust.

- Silent ventilation guarantees good recovery conditions for the patient

- Reduced need for maintenance work that create disturbances for the daily activities

Planning Tips / Checklist

- Min air flow in the room: 12,5 l/s (floor area 25 m²)

- Max air flow in the room: 38 l/s (loads = 370 W and ∆T=8°C)

- Supply air duct: ø 125mm (v=3,1 m/s with max air flow)

- Exhaust air duct: ø 125mm (0,4 Pa/m)

- OPTIVENT® ULTRA: ULDA-5-125-1 for supply and exhaust (same size as duct)

- Silencer: BDER-44-012-060 for supply and exhaust (36 dB(A) right after silencer with q=38 l/s and ∆P=80 Pa)

- Air pattern (diffuser DYVB-125): max air velocity < 0,15 m/s in the occupational zone with minimum air flow and 0,16 m/s with maximum air flow

Mass List: Hospital / Patient Room

Air management

- Optivent Ultra VAV-damper ULDA-5-125-1 (2 pcs)

- Silencer, length 600mm, BDER-44-012-060 (2 pcs)

Air diffusion

- Wall nozzle diffuser (2 pcs) with CleanVent® coating DYVZ-125 and ATVA-125-1

- Exhaust grille with CleanVent® coating SV1-550-200 and TGE-550-200-B

Automation systems

- Room Controller (Modbus connection) STRA-04

- Transformer STRZ-24-1

- CO2 -sensor STRZ-18-1-2

- External temperature sensor STRZ-05-04

- PIR Occupancy detector STRZ-09-1

Hospital Ventilation Products

-

GLWH 2012–4120 CD2.R (38 - 400 kW) (reversible)

GLWH 2012–4120 CD2.R (38 - 400 kW) (reversible)

- Version as water-to-water heat pump with reversible refrigeration circuit

- Saves space while taking into account optimum service accessibility

- 2 or 4 scoll compressors

- Refrigerant R-410A

-

Fresh Heaven MAXX O POWER LAMINAR AIRFLOW UNIT

Fresh Heaven MAXX O POWER LAMINAR AIRFLOW UNIT

- Complete filtration of operating area with a function to mix supply air (from AHU) and recirculating air

- Easy installation, maintenance and disinfection

- Low initial pressure drop of HEPA filters

- Tailored dimensions with LED lighting and control unit