Plate heat exchangers are efficient and reliable options for air-to-air energy transfer, which capture thermal energy from exhaust air to preheat incoming fresh air. However, in the cold climates, these systems are at risk. As the temperature of the incoming air decreases, water in the outgoing air starts to condensate and can cause frost buildup. This frost blocks the airflow, which reduces heat transfer efficiency and increases pressure drop and can, if unmanaged, completely clog the heat exchanger. This could result in significant operational delays, reputational damage, and potential financial losses—challenges that must be proactively mitigated.

Traditional defrost solutions offer the use of dampers for the cold outdoor air to bypass the heat exchanger, whilst the warm extract air still passes through the heat exchanger melting any ice that has formed. The reduction of heat recovery increases the energy demand.

However, it is possible to achieve both effective frost protection and optimal heat recovery efficiency. This approach also helps reduce the heating coil load, leading to lower running costs.

Protect Your Operations with Advanced Frost Protection Technology

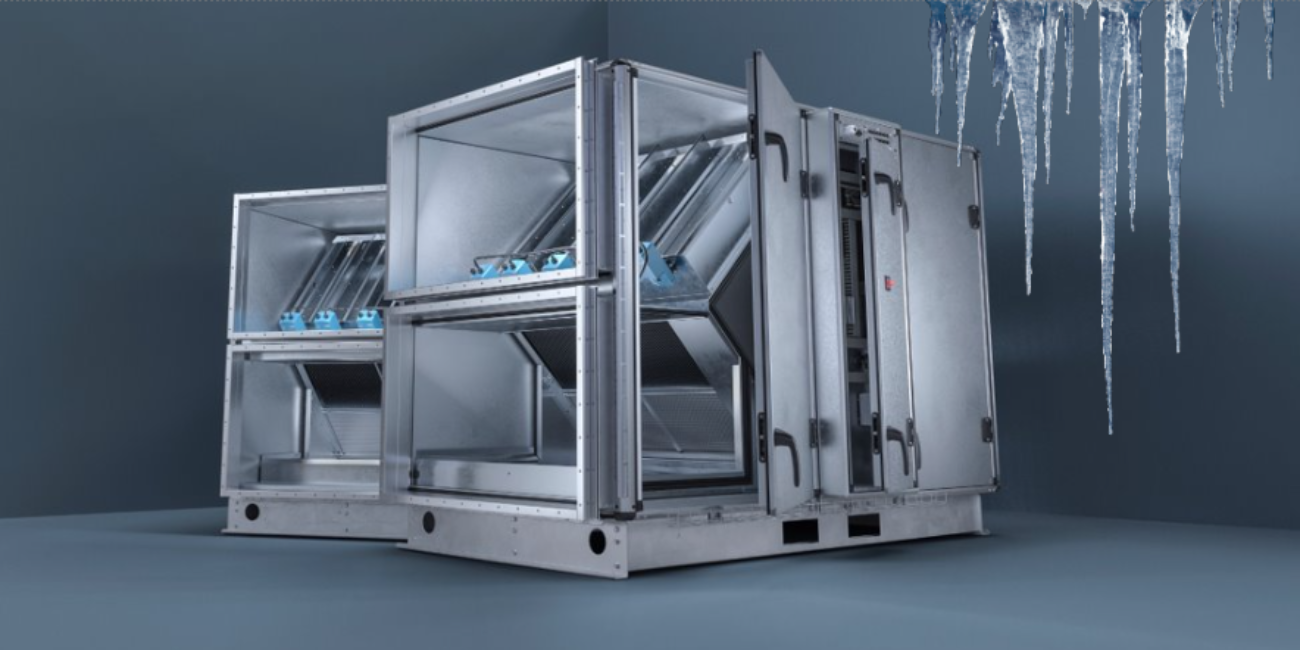

Advanced frost protection (AFP) is available for all eQ Prime & Master unit fitted with counterflow or crossflow plate heat exchangers. Designed for robust performance even in extreme conditions, the AFP system combines advanced technology and intelligent design to deliver unmatched energy efficiency and reliability.

Key Features:

- 4-face damper + bypass damper - Enhanced efficiency during defrost cycle

- Optimised defrost control - Extract air temperature and humidity are measured to activate defrost only when necessary

- Advanced software algorithms - Ensures precision control and optimises defrost activation

- High heat recovery efficiency - 56% efficiency during defrost cycles, even at temperatures as low as -32°c

- No pre-heater required - Operates efficiently without a pre-heater down to -32°c external temperatures

- Reduced post-heater size - Lowers total installation cost

Top Five Market Advantages

- Lowest post-heater capacity demand - High heat recovery efficiency minimises stress on the post-heater operation

- Lowest pre-heater demand - Operates without the need for pre-heating at the lowest admissible temperatures

- Exceptional robustness - Fewer sensors reduce potential failure points and increase reliability

- Minimised pressure variation - Stable airflow and reduced wear where dampers limit ice formation and prevent sudden pressure fluctuations. Fans and control systems subsequently experience less wear and tear

- Predicitive efficiency and stability - Consistent supply air temperatures with reduced wear on valves and actuators minimises efficiency fluctuations during defrost. And reduces power peaks and mechancial wear on key components

Maximize Performance with FläktGroup’s Advanced Frost Protection

- Continuously delivers a high and stable efficiency during defrost

- Smaller post heater

- Lower total cost of installation

- Ideal for climates with a dimensioning temperature below -8°C

Setting a New Standard in Frost Protection

What sets AFP apart towards a brighter future?

The most common approach to defrost is using defrost algorithms that works intermittently, i.e. on/off mode that changes between full recycle and defrosting. However, we have chosen a different path in which we constantly maintain a high efficiency and avoid fluctuations.

We believe that an intermittent solution works well when it is relatively warm winter climate (a few degrees below zero) and dry indoors (say maximum 30%RH). Then you can spend plenty of time in the full recovery mode.

The problem, however, is that this is not the norm, as warmer winter weather is usually associated with a more humid indoor climate (say over 30% in the building). Or if it is drier indoors, then it is usually significantly colder outside. An intermittent solution then builds up a lot of frost in a relatively short time in full recycling, which leads to frequent defrost cycles and low efficiencies (and high pressure drops) during defrosting.

Most technologies in the market only use two face dampers + a bypass. This means that once they activate their de-frost, they are by-passing 50% of the plate reducing efficiency. The FläktGroup system with 4 face dampers means we only by-pass 25% of the plate when de-frost is activated which increase efficiency.

In addition, the FläktGroup solution has an adaptive start, which take the air conditions into account, to only start defrosting until it is really needed.

What makes this technology so INNOVATIVE?

Our solution has a small, marginal, extra cost of supply (from FläktGroup) but reduces the total cost of installation at the same time as delivering reduced operating costs for building owners or operators.

- It achieves an extremely stable operation both in terms of efficiency and pressure drop

- It aligns with our company’s desire to offer the highest possible efficiency even when this adds to the cost of supply

- It is a direct contributor towards the target of net zero buildings.

The Future of HVAC with FläktGroup

At FläktGroup, we are constantly developing key technological features, such as defrosting of plate heat exchangers. For the upcoming period, we are testing at least 4 new concepts including a mix of software and mechanical features.

What we currently are focusing on is to further reduce the dependency of the defrost function, to increase redundancy and resilience of the entire heat recovery system. We are also testing smart functions with the potential to prolong the start of defrosting, such as weather forecasts etc.

AFP is currently available in our eQ Prime and Master air handling units. This technology will be implemented to more systems in the coming future.